par TDG Gold Corp. (isin : CA87190J1057)

TDG Gold Reports Gold-Silver Results From Historical Tailings At Baker, Toodoggone, BC

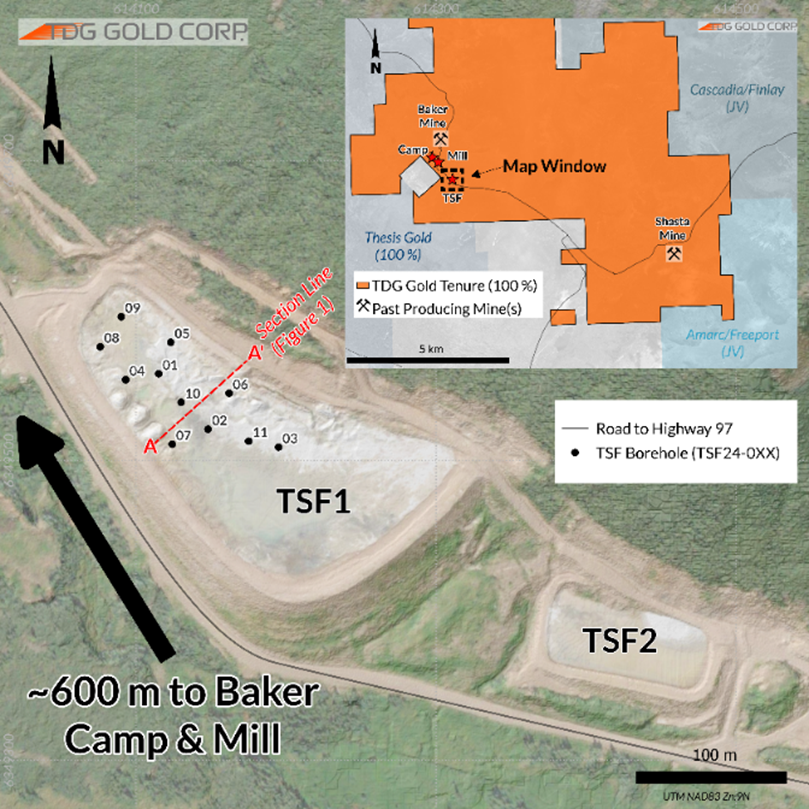

WHITE ROCK, BC / ACCESSWIRE / November 12, 2024 / TDG Gold Corp (TSXV:TDG) (the "Company" or "TDG") today reported assay results from the Phase 1 drilling of the main Tailings Storage Facility ("TSF1") located adjacent to the Baker Mill. TSF1 is reported to contain ~265,000 metric tonnes ("MT") of wet tailings from historical production at the former high-grade gold-silver ("Au-Ag") Baker and Shasta mines between 1981-20121. TDG completed 15 boreholes in TSF1 seeking environmental, geotechnical and geological data.

Highlights Include:

Aggregate length-weighted average grade of all tailings material sampled (Table 1) of 1.00 grams per tonne ("g/t") Au, 46 g/t Ag [1.57 g/t gold equivalent ("AuEq"2)]

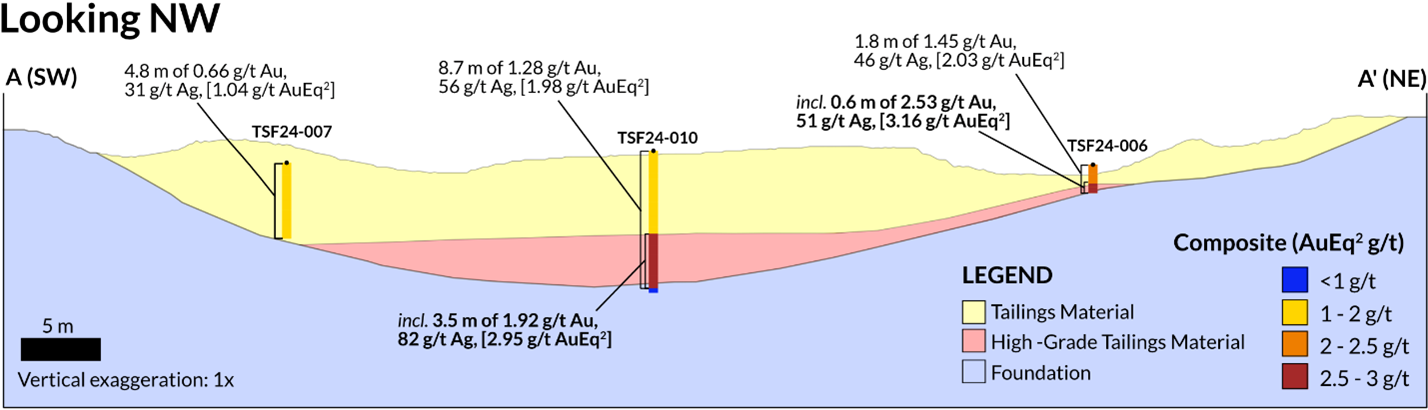

Two distinct strata identified within TSF1 (Figure 1) with higher grade material at the base (e.g., TSF24-010 reporting 3.5 m of 1.92 g/t Au and 82 g/t Ag [2.95 g/t AuEq2] (Table 1) overlain by more typical, moderate grade material

Au-Ag grades and calculated TSF1 volumes are in line with historical reported production records and recoveries1

Figure 1. Baker Schematic TSF Section with: (i) Foundation/Berm in light blue, (ii) Interpreted ‘High-Grade Tailings Material' in red, (iii) Interpreted ‘Tailings Material' in yellow

A second, smaller TSF ("TSF2") reportedly received ~50,000 MT of wet tailings material from the final years of the Shasta production1 may be analysed in subsequent work phases. Both TSFs at Baker are located within the Baker-Shasta Permitted Mine Area proximal (~ 600 m) to the Baker mill and other existing infrastructure, including the major mining road that connects the district (Figure 2).

Steven Kramar, TDG's VP Exploration, commented: "The Phase 1 assay results from TSF1 merit follow up to evaluate the remainder of TSF1 and all of TSF2 to determine the potential for reprocessing and relocation of the historical tailings as part of TDG's ongoing commitment to clean-up and remediation of the historical mining that took place at Baker-Shasta."

Options for Future Tailings Storage

In summer 2024, TDG also commissioned a review of the dry-stack tailings storage capacity within the footprint of the Permitted Mine Area and TDG's surrounding mineral tenure. Preliminary work by independent consultants has identified possible locations for potential dry-stack tailings storage with capacity sufficient for the entire current Shasta mineral resource (see news release May 1, 2023 for details of the mineral resource)3 such to be supported by future studies.

Figure 2. Map of the Baker TSFs and Borehole locations relative to existing Infrastructure.

Table 1. Composite Assay Results from Baker TSF Drilling 2024.

Borehole | From | To | Length | Au | Ag | AuEq |

(m) | (m) | (m) | (g/t) | (g/t) | (g/t) | |

TSF24-001 | 0.0 | 6.3 | 6.3 | 0.88 | 41 | 1.39 |

incl. | 3.8 | 6.3 | 2.5 | 1.18 | 50 | 1.81 |

TSF24-002 | 0.0 | 8.1 | 8.1 | 1.20 | 50 | 1.83 |

incl. | 4.8 | 8.1 | 3.3 | 1.78 | 65 | 2.59 |

and incl. | 4.8 | 7.1 | 2.3 | 2.00 | 77 | 2.96 |

TSF24-003 | 0.0 | 6.3 | 6.3 | 0.86 | 41 | 1.37 |

TSF24-004 | 0.0 | 2.5 | 2.5 | 0.78 | 40 | 1.28 |

TSF24-005 | 0.0 | 2.1 | 2.1 | 0.50 | 35 | 0.94 |

TSF24-006 | 0.0 | 1.8 | 1.8 | 1.45 | 46 | 2.03 |

incl. | 1.2 | 1.8 | 0.6 | 2.53 | 51 | 3.16 |

TSF24-007 | 0.0 | 4.8 | 4.8 | 0.66 | 31 | 1.04 |

TSF24-008 | 0.0 | 1.8 | 1.8 | 0.69 | 40 | 1.19 |

TSF24-009 | 0.0 | 2.3 | 2.3 | 0.83 | 54 | 1.51 |

incl. | 1.8 | 2.3 | 0.5 | 1.21 | 100 | 2.46 |

TSF24-010 | 0.0 | 8.7 | 8.7 | 1.28 | 56 | 1.98 |

incl. | 5.3 | 8.7 | 3.5 | 1.92 | 82 | 2.95 |

TSF24-011 | 0.0 | 8.8 | 8.8 | 1.08 | 52 | 1.74 |

incl. | 6.6 | 8.8 | 2.3 | 1.14 | 56 | 1.83 |

Aggregate (Tailings) | 41.1 | 0.81 | 40 | 1.32 | ||

Aggregate (High-Grade) | 12.4 | 1.61 | 66 | 2.43 | ||

Aggregate (All Samples) | 53.4 | 1.00 | 46 | 1.57 |

* Intervals are length weighted. True width is estimated between ~ >99% % of length; recovery is estimated to be > 90 %

** Composite result was calculated using 0.5 g/t AuEq2 cut-off, but there may be intervals within the composite below 0.5 g/t AuEq2.

*** Calculated composites are truncated to two significant decimal places for Au and the nearest integer for Ag.

**** Calculated composite may not sum due to rounding.

***** ‘Aggregate' results are a summation of metres. It is an uncut and uncapped length weighted composite.

2024 TSF Investigation

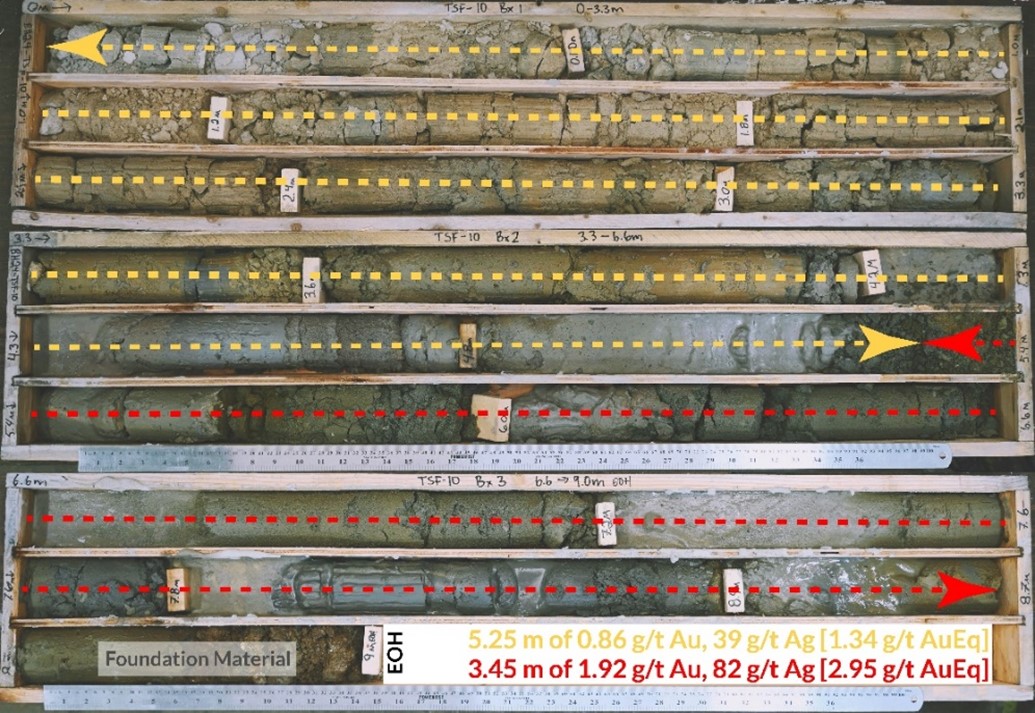

Based on initial interpretations from geological observations and geochemical analysis, the tailings material in TSF1 can be divided into three parts (Figure 3): (i) the ‘Tailings Material' comprising the majority of the tailings from 1989-2012 (shown in gold), (ii) the interpreted ‘High-Grade Tailings Material' deeper into the TSF1 pile from 1981-1983 (shown in red) and (iii) the foundation material at the base of the TSF (shown in grey). Potential metallurgical recoveries for the tailings have not been determined but will be evaluated in future studies.

‘Tailings Material'

Tailings Material consists of mill tails from production start in ~1989 until ultimate final closure of the mill in 20121 (~80 % of the tailings that reported1 to TSF1). This material has an aggregate length weighted grade of 0.81 g/t Au and 40 g/t Ag [1.32 g/t AuEq2], which is similar grade to TDG's estimate of the mineral resources "MRE"3) at Shasta (news release May 1, 2023 for details of the MRE3). The material can be described as sand dominant with centimetre ("cm") scale laminations of darker silty material. Overall, sulphide mineral content is estimated to be less than 5 %.

‘High-Grade Tailings Material'

The Higher-Grade Tailings Material is interpreted from the earliest generation of mining the Baker A-Vein (1981-1983) and is thought to coincide with higher head grades to the mill (> 30 g/t Au1) and moderate recovery from the start of mining operations1. This strata accounts for ~20 % of the tailings that reported1 to TSF1 and, based on the holes interpreted to intersect this material, has an aggregate length weighted average grade of 1.61 g/t Au and 66 g/t Ag [2.43 g/t AuEq2] (Table 1), which is significantly higher than TDG's estimate of the MRE3 at Shasta. The material can be described as silt-dominant, with intercalated layers of sandy material. Sulphide mineral content is generally ~5 % or greater.

‘Foundation Material'

The base of the TSF impoundment appears to be a mixture of coarse rocks and gravel. Follow-up work is necessary to investigate the potential of concentration of precious metals at the base or into the foundation material due to the ‘placer effect' of gravity.

Figure 3. TSF24-10 with: (i) Interpreted ‘Tailings Material' in gold, (ii) Interpreted High-Grade Tailings material in red, (iii) Interpreted Foundation material in grey

QA/QC

Samples for the Baker TSF drill program were handled via rigorous chain of custody, including sample collection, processing, and delivery to the Bureau Veritas ("BV") in Vancouver, B.C. The material was logged, photographed, and sampled at TDG's Baker Mine site and processed by geologists and technicians. Quality assurance and control ("QAQC") materials were inserted into the sampling sequence during geological sample selection. The material selected for sampling was placed in zip-tied polyurethane bags, then in security-sealed rice bags before being delivered directly by TDG staff from the Baker mine site to Bandstra Transportation Systems in Prince George, ultimately to the BV facility in Vancouver, B.C. Samples were prepared and analyzed following procedures: PRP90-250 for sample preparation, FAS430 for Au and AQ251 for Ag and trace elements. Overlimit concentrations (> 100 ppm Ag) of precious metals will be analyzed (where applicable) by MA401. Information about methodology can be found on the BV Labs website, in the analytical guide (here).

QAQC is maintained internally at the lab through rigorous use of internal certified reference materials ("CRMs"), blanks, and duplicates. An additional QAQC program was administered by TDG through the verification of lab results via use of CRMs and blank (unmineralized) samples that were blindly inserted into the sample batch. If a QAQC sample returns an unacceptable value an investigation into the results is triggered and when deemed necessary, the samples that were tested in the batch with the failed QAQC sample are re-tested.

Table 2 presents the particulars for the boreholes in this news release. During the sampling process, material was consumed in entirety. The collar location was located using Global Positioning System ("GPS") using hand-held systems.

Table 2. Borehole Collar Information.

HOLE | UTME NAD83 (mE) | UTMN NAD83 (mN) | Azimuth(°) | Dip(°) | Final Depth (m) |

TSF24-001 | 614,115 | 6,349,558 | 0 | 90 | 6.6 |

TSF24-002 | 614,148 | 6,349,521 | 0 | 90 | 8.4 |

TSF24-003 | 614,195 | 6,349,509 | 0 | 90 | 6.6 |

TSF24-004 | 614,093 | 6,349,554 | 0 | 90 | 3.0 |

TSF24-005 | 614,123 | 6,349,579 | 0 | 90 | 2.4 |

TSF24-006 | 614,162 | 6,349,545 | 0 | 90 | 1.8 |

TSF24-007 | 614,124 | 6,349,511 | 0 | 90 | 4.8 |

TSF24-008 | 614,076 | 6,349,576 | 0 | 90 | 2.4 |

TSF24-009 |